Hardwood Floor Underlayment: What It Is & Why It Matters

When you’re investing in new hardwood floors, you want to make sure the installation is done right the first time. One detail that’s often overlooked—but plays a major role in how your floor feels, sounds, and lasts—is the hardwood floor underlayment.

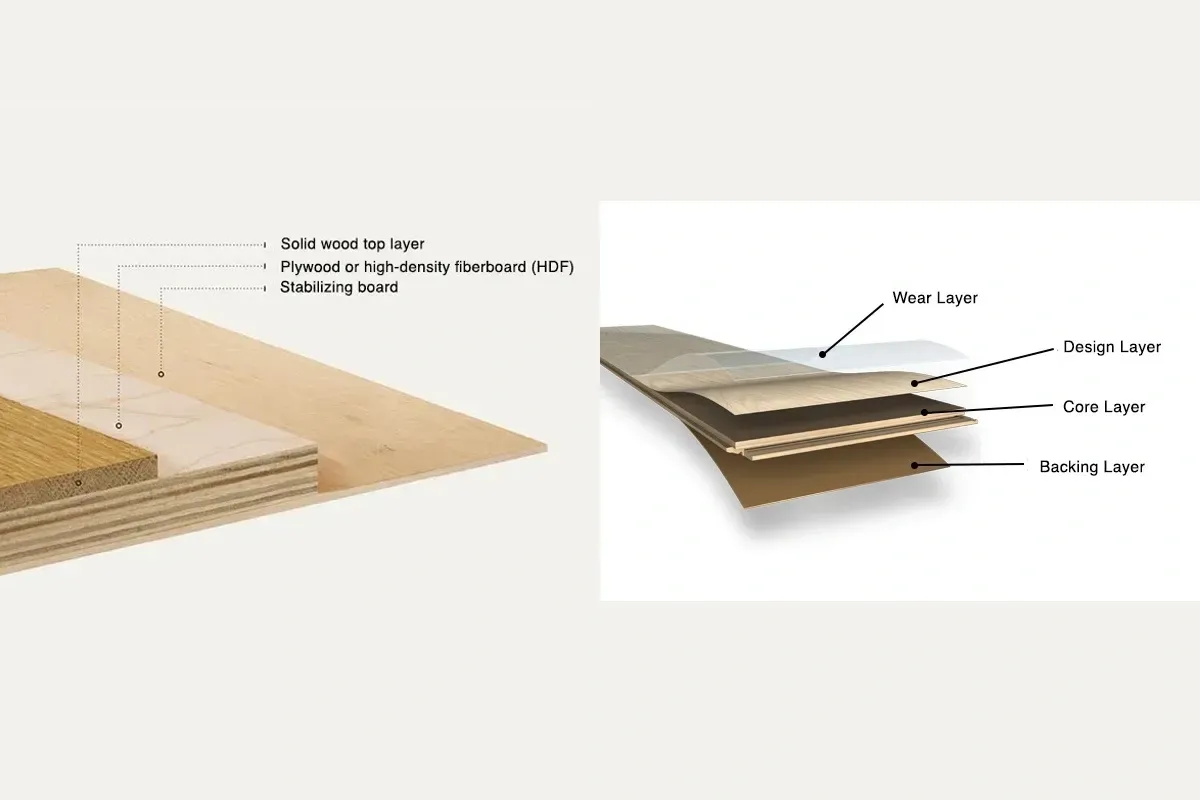

Underlayment is the thin layer of material installed between your subfloor and the hardwood planks. It may not be the most visible part of the project, but it can make a huge difference in performance and comfort. To be clear, an underlayment, as it relates to hardwood flooring, could be plywood, sound deadening padding, or both.

At Rejuvenation Floor & Design, we help homeowners understand their flooring options from top to bottom—literally. This guide will cover whether hardwood flooring really needs underlayment, why it matters, the different types of hardwood floor underlayment available, and along with installation methods.

TL;DR: Hardwood floor underlayment is the thin layer between your subfloor and hardwood planks that improves comfort, stability, and longevity. While not always required for solid hardwood, it’s essential for floating or engineered floors and concrete subfloors. The right underlayment—whether plywood, Aquabar, rubber, or cork—adds moisture protection, reduces noise, smooths imperfections, and extends the life of your floors.

Does Hardwood Floor Need Underlayment?

Whether or not you need hardwood floor underlayment depends on the type of flooring you’re installing and the condition of your subfloor.

- Solid Hardwood: Traditionally,

solid hardwood planks are nailed or stapled directly to a wooden subfloor, so an additional underlayment isn’t always necessary. The subfloor itself acts as the main support. However, moisture barrier or felt paper are sometimes used under solid wood to reduce squeaks and protect against seasonal moisture changes.

- Engineered Hardwood: If you’re installing a floating

engineered hardwood floor, underlayment is almost always necessary.

Floating floors aren’t nailed or glued down—they rely on the underlayment for stability, cushioning, and noise reduction. Even when engineered hardwood is glued down, a moisture barrier built into the adhesive may be necessary depending on circumstances.

- Concrete Subfloors: If you’re installing floating hardwood over concrete, an underlayment and moisture barrier are typically required. Concrete holds moisture, which can damage wood over time. A proper vapor barrier helps prevent warping, cupping, or mold growth.

In short, while not all hardwood floors technically require underlayment, most installations benefit from it. Skipping this step can lead to creaky boards, moisture issues, or a less comfortable walking surface.

Why Use Underlayment for Hardwood Floor?

Hardwood floor underlayment serves several key purposes that go beyond simply filling space under the floor:

1. Moisture Protection

Wood is sensitive to moisture, and even small amounts can cause swelling, warping, or mold. Hardwood floor underlayment and vapor barriers protect your flooring investment by blocking moisture from below—especially crucial over concrete slabs, basements and crawl spaces that aren’t well insulated.

2. Noise Reduction

Squeaky wood floors can be frustrating, especially in multi-level homes. Underlayment cushions the planks slightly, absorbing some of the impact sound when you walk and reducing hollow echoes. This is particularly helpful in upstairs bedrooms or condos where sound transmission can be an issue.

3. Subfloor Imperfection Coverage

Even small dips or uneven areas in a subfloor can cause problems for a hardwood installation. Underlayment helps smooth out minor imperfections so your floor sits flatter and more stable, preventing creaks and premature wear.

4. Improved Longevity

When moisture, noise, and subfloor imperfections are controlled, your hardwood floor can last longer with fewer problems. Underlayment essentially helps create a more controlled environment for your planks, which supports their long-term performance.

Hardwood Floor Underlayment Options

Not all underlayment is the same, and choosing the right one for your home is crucial. Here are the most common hardwood floor underlayment options:

1. Plywood Underlayment

Plywood is the most common underlayment installed under ¾” thick solid hardwood that is being nailed or glued down. Currently, the National Wood Flooring Association (NWFA) approves the use of OSB plywood under solid hardwood flooring, but not particle board.

2. Aquabar Underlayment

Aquabar is often used under nail-down solid hardwood installations. It provides a thin layer of moisture barrier to protect the homes’ main level hardwoods from moisture transferred up from the crawl space.

3. Rubber Underlayment

Rubber is a premium option that provides excellent sound absorption and cushioning. It’s especially popular in condos, apartments, or upper floors where noise reduction is a priority. Many rubber underlayments include a moisture barrier as well. These are used specifically with floating hardwood. Be prepared for added costs, as rubber is thicker, heavier and more difficult to install than Aqua Bar.

4. Cork Underlayment

Cork is a natural and eco-friendly option that provides good sound insulation and thermal benefits. It can also resist mold and mildew. Cork underlayment is a great choice for homeowners seeking a green building material, though it may require a separate moisture barrier.

How to Install Hardwood Floor Underlayment

The exact hardwood floor underlayment installation process varies by underlayment type and floor system, but here’s a general overview of what homeowners can expect:

- Prepare the Subfloor: The subfloor must be clean, dry, and level. This step is crucial—hardwood floor underlayment won’t fix major dips or structural issues. Installers typically sweep or vacuum the surface, repair damage, and ensure the subfloor meets flatness tolerances.

- Lay the Underlayment: For

floating floors, the underlayment is rolled out across the room, with seams taped or overlapped according to the manufacturer’s instructions.

- Seal the Seams (if required): When using a moisture barrier, seams are taped to create a continuous layer of protection. This prevents moisture from seeping through gaps.

- Install the Flooring: Once the underlayment is properly in place, the hardwood installation proceeds as normal—whether that means clicking planks together for a floating floor, nailing solid hardwood, or gluing engineered planks.

- Inspect and Finish: Installers make a final check to ensure there are no visible gaps or issues. Then baseboards and trim are installed to cover expansion gaps and complete the look.

Final Thoughts

Hardwood floor underlayment might not be the first thing that comes to mind when planning your hardwood flooring project, but it plays a big role in performance, comfort, and longevity. Whether you choose plywood, felt, rubber, cork, or a combination, the right product helps protect your investment and makes your floor a joy to walk on.

If you’re considering new hardwood flooring but aren’t sure which underlayment option is right for your space, Rejuvenation Floor & Design can help. Our team can inspect your subfloor, explain your options, and recommend the best combination of materials for a quiet, durable, and beautiful floor. We encourage local homeowners to stop by our flooring store in Portland, Oregon and speak with one of our specialists.